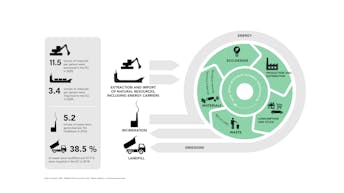

There is only one planet Earth, yet by 2050, the world will be consuming as if there were three. Global consumption of materials — such as biomass, fossil fuels, metals and minerals — is expected to double in the next forty years, while annual waste generation is projected to increase by 70% by 2050 [1].

The construction sector, in particular building and demolition, represents the largest waste stream in the EU. In fact, in 2018, the buildings and construction sector accounted for 36% of final energy use and 39% of energy and process-related carbon dioxide (CO2) emissions, 11% of which resulted from manufacturing building materials and products such as steel, cement, and glass [2]. In the same year, the total waste generated in the EU by the construction industry amounted to roughly 813 million tonnes — contributing 35.7% of the total [3].